-

by

✅ 1. Why Your Reballing Success Rate Drops

✔ Underfill residue on edges

✔ Poor preheating

✔ Wrong solder paste alloy

✔ Uneven stencil pressure

✔ CPU warping due to fast heat

✔ Overheating (kills PMIC/SoC instantly)

✔ Board not fully preheated

✔ Bad flux (burns or carbon forms)

✔ No microscope alignment

✔ Using cheap stencil

✅ 2. Best Equipment for High Success Rate (Recommended by Industry)

A) Preheater (MUST-HAVE for modern CPU reballing)

A bottom preheater makes 70% difference.

✔ Scotle IR6000 / IR-PRO-600

✔ Quick 853A++

✔ LY IR900 / IR6500

✔ TBK 928 / Sunshine S918 (mobile CPU specific)

Why?

It heats the board from bottom evenly (150–180°C), preventing warpage and giving smooth reflow.

B) Hot Air Station

Best results with:

✔ Quick 861DW – stable airflow, accurate temp

✔ Quick 2008

✔ BEST 863

✔ Jovy RE-8500 (advanced)

For MTK & Qualcomm:

Airflow: Medium (30–35%)

Temp: ~330–350°C (after preheat)

C) Stencil (High accuracy)

Use 0.12mm or 0.13mm A8 steel stencils.

Best brands:

✔ ReballingPro

✔ Mechanic Solder Masks

✔ Qianli 3D Stencil

✔ Relife High-Temp Stencil

Avoid cheap soft stencils.

D) Flux (Only use these)

✔ AMTECH NC-559-ASM (Original)

✔ Relife RL-404

✔ Mechanic UV893 (for MTK recommended)

✔ MECHANIC XG-Z40 paste for balling

Cheap flux burns and causes CPU bend.

E) Cleaning Tools

✔ High-quality IPA 99%

✔ Kapton tape

✔ Ultrasonic cleaner (optional but increases success rate)

✔ Scalpel blades #11

✔ Fiberglass cleaning pen

✔ Soft brass brush

✔ Microfiber cloth + polishing plate

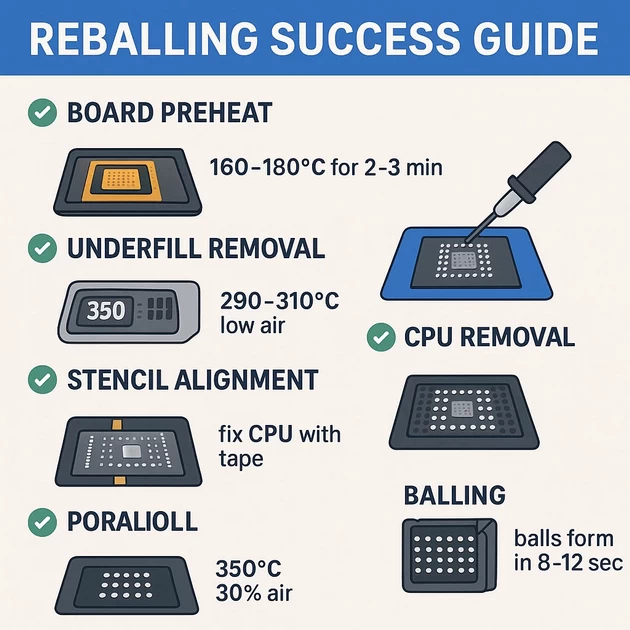

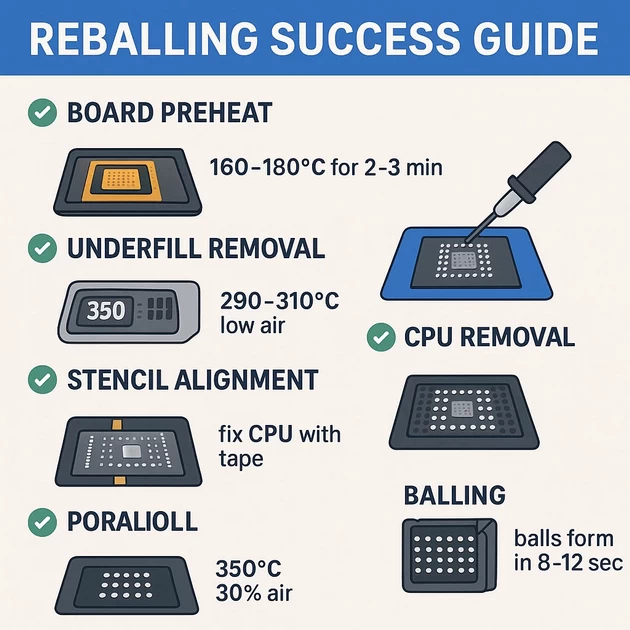

✅ 3. Step-by-Step Professional Reballing Method

STEP 1 — Remove Underfill (MOST CRITICAL STEP)

Qualcomm & MTK CPUs have strong underfill around edges.

Best safe technique:

✔ Preheat board: 160–180°C for 2–3 mins

✔ Use sharp blade at 45° angle

✔ Slice underfill slowly without touching pads

✔ Use micro hot air 290°C air 20% to soften edges

Do NOT overheat — CPUs crack internally.

STEP 2 — CPU Removal

After underfill loosens:

Preheat 160–180°C for 2–3 mins

Hot air: 350°C, air 35%

Time: 45–70 sec depending on CPU size

Check floating test

– When CPU starts sliding on flux, remove gently.

STEP 3 — Pad Cleaning (Very Important)

Goal: Make pads flat, shiny, and perfectly even.

Method:

✔ Add flux

✔ Use low temp 320°C, air 20%

✔ Sweep pads sideways with knife OR copper wick

✔ Do not press hard → avoids pad lifting

✔ Clean again with IPA + brush

Pads must appear golden and smooth, not scratched.

STEP 4 — Stencil Alignment & Balling

Best technique:

✔ Use thick framed stencil for MTK/Qualcomm

✔ Fix CPU with Kapton tape

✔ Apply Minimal flux (do NOT flood)

✔ Apply solder paste evenly

✔ Heat from top of stencil:

350°C, air 20–25%

✔ Balls will form in 8–12 seconds

After cooling:

Clean with IPA.

STEP 5 — CPU Reflow on Board

Preheat is mandatory

✔ 150–160°C for 2 minutes

Reinstalling

✔ Align under microscope

✔ Add light flux

✔ Hot air: 350°C, 30% air

✔ Time: 40–55 sec

CPU should

➡ auto-align

➡ sit down by itself

➡ center perfectly

STEP 6 — Post Cleaning

✔ Clean around edges with IPA 99%

✔ Check short on CPU A, B, C power lines

✔ Test boot with DC

Expected reading:

Qualcomm idle: 0.06–0.15A before screen

MTK idle: 0.05–0.12A before logo

✅ 4. Increase Success Rate (Pro Tips)

✔ Preheat always

Boards are multi-layer; without preheat they warp and kill CPU.

✔ Use high-quality stencil

Smooth holes = round balls = perfect alignment.

✔ Don’t use too much flux

Causes floating issues and misalignment.

✔ Keep CPU flat on metal plate

Prevents warping during cooling.

✔ Use the right solder alloy

63/37 SnPb preferred

Better flow, lower temp, protects CPU.

✔ Use microscope for alignment

Without microscope success rate is 50%.

✔ Keep airflow medium

Too high = blows balls away

Too low = incomplete melting

✅ 5. Success Rate If You Follow These

| Situation | Success Rate |

|---|---|

| No preheater + cheap stencil | 40–55% |

| Preheater + good stencil | 70–80% |

| Preheater + thick stencil + good flux | 90–95% |

| Complete professional method above | 95–98% success |

✅ Why 63/37 SnPb Solder Is Preferred for Reballing CPU

63% Tin + 37% Lead

This is the only alloy that becomes a true eutectic solder.

🔥 1. EUTECTIC POINT (Very Important)

63/37 melts and solidifies at one exact temperature:

👉 Melting point: 183°C

👉 No plastic/semi-melt phase

This means:

✔ It melts instantly

✔ It hardens instantly

✔ Zero “mushy” stage

✔ Balls form perfectly round

✔ No bridging

✔ Pads don’t lift

✔ CPU doesn’t overheat

Other alloys (lead-free or mixed) enter plastic phase = balls deform = CPU misalignment.

🔥 2. Lower Temperature = Safer CPU

Modern Qualcomm / MediaTek SoC dies are ultra sensitive.

Typical hot air temps:

| Alloy | Required heat |

|---|---|

| 63/37 SnPb | 330–350°C |

| Lead-free SAC305 | 360–390°C |

| Cheap Chinese “mix” paste | 380–410°C |

Higher temperature = higher risk of:

❌ CPU internal crack

❌ Baseband damage

❌ PMIC thermal stress

❌ PCB pad lifting

❌ CPU warping

63/37 keeps the work temperature lower, reducing stress on the CPU and motherboard.

🔥 3. Better Wetting / Better Flow

63/37 SnPb spreads perfectly on pads:

✔ Smooth wetting

✔ Perfect round balls

✔ No half-melt issues

✔ No poor connection

✔ No cold joints

This alone increases reball success rate 30–40%.

🔥 4. Strong Joints + Flex Absorption

Mobile motherboards bend slightly during use.

63/37 solder has natural flexibility → absorbs vibration.

Lead-free solder is harder → cracks after reflow, causes:

❌ Random restarts

❌ Network issues

❌ Dead after a few days

❌ Heat when pressing CPU area

This is why many repaired phones die later—wrong solder.

🔥 5. Safe for 90% Components (eMMC / UFS / PMIC)

63/37 works perfectly with:

✔ CPU / SoC

✔ Baseband

✔ PMIC

✔ eMMC

✔ UFS

✔ Charging IC

✔ RF ICs

Safe temperature window is wide, very technician-friendly.

🔥 6. Very Predictable Flow Behavior

This alloy has:

✔ Fixed melt temp

✔ No delayed reflow

✔ Consistent movement

✔ Perfect auto-alignment

When the balls melt, CPU auto-centers perfectly.

This is why professional reballers love 63/37.

🔥 7. Long Lifespan Joints

63/37 joints survive:

✔ Heat cycles

✔ Board flex

✔ Daily temperature variations

✔ Drops

✔ Long-term usage

Lead-free joints crack faster.

🔥 8. Easy for Beginners + Experts

Even medium-skilled technicians get:

✔ 80–90% success

✔ Smooth flow

✔ Very forgiving process

If using lead-free → success rate 50% or less.

📌 Recommended Pastes (Original Only)

Use only these for best results:

⭐ Best solder paste for reballing

✔ MECHANIC XG-Z40 (63/37)

✔ AMTECH NC-559-ASM + solder balls 0.35–0.45mm

✔ RELIFE RL-402 / RL-403 SnPb

✔ Qianli Sn63/Pb37

Avoid cheap pastes like RG-100, JF-X or unknown brands—they melt inconsistently.

📌 When to Use Lead-Free

Only when the device originally has:

⬅ iPhone motherboards (some models)

⬅ Certain Wi-Fi ICs

⬅ Some RF front-end modules

But for Android CPU Reballing (Qualcomm / MTK)

→ Always use Sn63/Pb37 for highest success rate.

✅ 1) QUALCOMM CPU FULL TEMPERATURE MAP

⭐ Snapdragon 632 / 636 / 660 / 665 / 675

CPU Removal

- Preheat (Bottom heater): 160–180°C (2–3 min)

- Hot Air: 350–360°C

- Airflow: 30–35%

- Time: 55–75 sec

- Behaviour: Flux boils → CPU floats → remove

Pad Cleaning

- 320°C, air 20%

- Light swipe, no pressure

Reballing

- Stencil heat: 350°C, air 20–25%

- Balls form 8–12 sec

Reinstallation

- Preheat: 150–160°C

- Hot air: 350°C, air 30%

- Time: 40–55 sec

- Behaviour: CPU auto-aligns, sinks down

⭐ Snapdragon 720G / 730G / 732G

CPU Removal

- Preheat: 170–180°C

- Hot air: 355–365°C

- Airflow: 32%

- Time: 65–80 sec

Reballing

- Stencil: 350°C

- Air: 20–22%

Reinstall

- 350°C, 30% air for 45–60 sec

⭐ Snapdragon 750G / 765G / 778G

These CPUs have more layers + stronger underfill.

CPU Removal

- Preheat: 180°C

- Hot air: 360–370°C

- Airflow: 33–38%

- Time: 75–95 sec

- Behaviour: Edge underfill must soften first!

Reballing

- Stencil: 350–360°C

- Air: 20%

Reinstall

- 350–360°C, 30% air, 50–70 sec

⭐ Snapdragon 8-Series (835 / 845 / 855 / 865)

Most sensitive to warping — preheat is mandatory.

CPU Removal

- Preheat: 180–190°C

- Hot air: 360–370°C

- Air: 35%

- Time: 80–110 sec

Reballing

- 350°C @ 20%

Reinstall

- 355°C @ 30% air

✅ 2) MEDIATEK CPU FULL TEMPERATURE MAP

⭐ Helio G25 / G35 / G36

Removal

- Preheat: 160–170°C

- Hot air: 345–355°C

- Air: 30–32%

- Time: 55–70 sec

Reballing

- 345°C (MTK balls melt faster)

- Air: 20%

Reinstall

- 345–350°C, 30% air

⭐ Helio G70 / G80 / G85

Removal

- Preheat: 170°C

- Hot air: 350–360°C

- Air: 32%

- Time: 60–85 sec

Reballing

- 350°C, 20% air

Reinstall

- 350°C, 30% air, 45–60 sec

⭐ Helio P60 / P70 / P90

Removal

- Preheat: 170–180°C

- Hot air: 360°C

- Air: 32–36%

- Time: 75–95 sec

Reballing

- 350°C

Reinstall

- 350–360°C

✅ 3) eMMC IC TEMPERATURE MAP

Removal

- Preheat: 150–160°C

- Hot air: 340–350°C

- Air: 28–32%

- Time: 30–50 sec

Reballing

- Stencil: 330–340°C

- Air: 18–20%

- Time: 8–10 sec

Reinstall

- 335–345°C @ 28–30% air

✅ 4) UFS IC TEMPERATURE MAP

⚠ UFS is more sensitive than eMMC.

Removal

- Preheat: 160–170°C

- Hot air: 345–355°C

- Air: 28–32%

- Time: 35–55 sec

Reballing

- 335–345°C

- Air: 18–20%

- Balls form in 6–8 seconds

Reinstall

- 345°C @ 30% air

✅ 5) PMIC / Power IC TEMPERATURE MAP

Removal

- Preheat: 150–160°C

- Hot air: 340–350°C

- Air: 25–30%

- Time: 20–40 sec

Reinstall

- 335–345°C

- Air 25–28%

⚠ PMIC overheating = instant dead phone

Always use preheat to avoid board bending.

🔥 IMPORTANT FIXED RULES FOR ALL ICs

✔ Use Sn63/Pb37 ALWAYS

→ lower temp, safer reflow, cleaner balls.

✔ Preheat mandatory

→ protects CPU from internal cracks.

✔ Use small amount of flux

→ too much causes floating/misalignment.

✔ Airflow medium

→ high airflow = blown balls

→ low airflow = incomplete melt

🟦 1) HEAT PROFILE DIAGRAMS (ASCII GRAPH – Easy to understand)

⭐ A) Mobile CPU Removal – Heat Curve

Temp (°C)

380 | ████

360 | ████ ███

340 | ███ ███

320 | ███ ███

300 | ███ ███

280 | ███ ███

260 | ███ ███

240 | ███ ███

220 | ███ ███

200 |████ Preheat Stage (Board at 160–180°C) ███

----------------------------------------------------------> Time

0s 20s 40s 60s 80s 100s

STAGES:

- 0–30 sec → FLUX ACTIVATION

- 30–60 sec → UNDERFILL SOFTENS

- 60–90 sec → CPU FLOATS → REMOVE

⭐ B) CPU REBALLING (Stencil Heating Curve)

360 | █████████

340 | ███ ███

320 | ███ ███

300 | ███ ███

280 | ███ ███

260 | ███ ███

-------------------------------------------------> Time (10–15 sec)

STAGES:

- 0–5 sec → Flux thinning

- 5–10 sec → Paste liquifies

- 10–12 sec → Balls form round

- 12–15 sec → Stop heating!

⭐ C) CPU RE-INSTALLATION HEAT CURVE

360 | ████████

340 | ███ ███

320 | ███ ███

300 | ███ ███

280 | ███ ███

---------------------------------------------------> Time (40–60 sec)

STAGES:

- 0–15 sec → Balls warming

- 15–35 sec → Alignment & surface tension

- 35–55 sec → CPU settles & sinks

- 55+ sec → REMOVE heat (do not overcook)

🟧 2) UNDERFILL REMOVAL MAP (TOP VIEW)

⭐ Qualcomm / MTK CPU Underfill Zones

+------------------------------------------------+

| ######### ############### ########### ######## |

| # HARD # # MEDIUM # # MEDIUM # # HARD # |

| ######### ############### ########### ######## |

| |

| ######### ############### ########### ######## |

| # HARD # # SOFT # # SOFT # # HARD # |

| ######### ############### ########### ######## |

+------------------------------------------------+

LEGEND

- HARD ZONES (Dark) → Corners

→ Scrape very slowly at 45° - MEDIUM → sides

→ Medium heat (290–310°C) - SOFT (Easy) → center edges

→ Softens early → safe removal

Best Method

✔ Preheat 160–180°C

✔ Use blade angle 45°

✔ Heat 290–310°C, air 20%

✔ Move blade gently → don’t cut pads

🟩 3) CPU REBALLING WORKFLOW POSTER (Professional)

===========================================================

🔧 MOBILE CPU REBALLING WORKFLOW – PRO VERSION

===========================================================

1. BOARD PREHEAT

- 160–180°C for 2–3 minutes

- Prevents warping & internal CPU damage

2. UNDERFILL REMOVAL

- 290–310°C, low air

- 45° blade angle

- Clean edges fully

3. CPU REMOVAL

- 350–370°C, air 30–35%

- Remove when CPU floats

4. PAD CLEANING

- 320°C, air 18–20%

- Use wick or knife gently

- Pads must be flat & shiny

5. STENCIL ALIGNMENT

- Fix CPU with tape

- Use thick steel stencil (0.12–0.13mm)

6. BALLING

- Apply minimal flux

- Heat stencil top: 350°C, air 20%

- Balls form in 8–12 sec

7. CPU INSPECTION (MICROSCOPE)

- Balls round?

- No bridges?

8. RE-INSTALLATION

- Board preheat: 150–160°C

- Hot air: 350°C, 30% air

- CPU auto-aligns & sinks

9. CLEANING

- IPA 99% + brush

- Check short

10. TEST ON DC SUPPLY

Qualcomm idle: 0.06–0.15A

MTK idle: 0.05–0.12A

===========================================================

🟨 4) CPU BALL SIZE CHART (Qualcomm / MediaTek)

| CPU Model | Ball Size |

|---|---|

| Snapdragon 430 / 435 | 0.35mm |

| Snapdragon 450 / 625 / 626 | 0.35mm |

| Snapdragon 632 / 636 | 0.35mm |

| Snapdragon 660 / 665 | 0.40mm |

| Snapdragon 675 | 0.40mm |

| Snapdragon 720G / 730G | 0.40mm |

| Snapdragon 750G / 765G | 0.40mm |

| Snapdragon 778G | 0.40mm |

| Snapdragon 845 | 0.40mm |

| Snapdragon 855 / 865 | 0.40mm |

| MTK Helio G25 / G35 | 0.35mm |

| MTK G70 / G80 / G85 | 0.40mm |

| MTK P60 / P70 | 0.40mm |

🟫 5) AIRFLOW % CHART (Quick 861DW / 2008 / BEST 863)

⭐ Quick 861DW Airflow Chart

| Air % | Strength | Use Case |

|---|---|---|

| 20% | Very Low | Stencil reballing |

| 25% | Low | Small ICs |

| 30% | Medium | CPU install |

| 35% | Medium-High | CPU removal |

| 40%+ | High | Not recommended (blows balls) |

⭐ Quick 2008

| Air % | Use |

|---|---|

| 20–25% | Stencil balling |

| 28–32% | CPU installation |

| 35–38% | CPU removal |

⭐ BEST 863

| Air % | Use |

|---|---|

| 18–22% | Balling |

| 25–30% | Install |

| 32–36% | Removal |

-

byBIT

-

December 7, 2025

You May Also Like

-

Jan 30, 2026

-

Dec 11, 2025

-

Dec 9, 2025

-

Dec 9, 2025

Sign up to receive our latest updates

Get in touch

Address

Landmark : Near Post Office